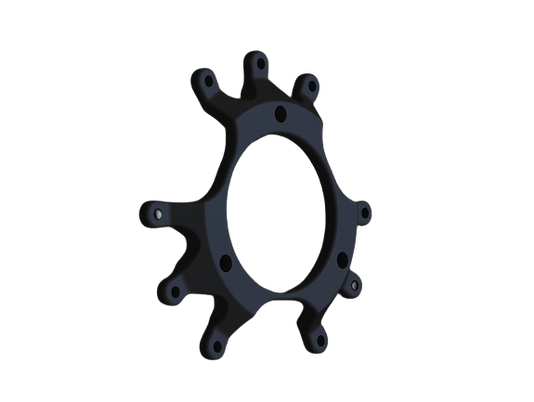

WHEEL CENTRE DESIGN

Reiteration and mass reduction of unsprung suspension mass

Solo Project - Sep 2020 to Dec 2020 | Vehicle Dynamics | FEA | Data Analysis

Summary

My first step into the world of chassis design.

This was my first project as a suspension engineer for the University of Toronto Formula Racing Team. My goal was to radically change the design of the existing wheel centre and reduce its overall mass without compromising the strength or stiffness of the part. The wheel centre is a structural component of the suspension assembly that connects the wheel hub to the rim. Once completed, I installed it on our car and tested its strength. Since 2020, we've been using it on our car in every competition!

Design Objectives

Reduce weight by 10%

Maintain Stiffness

Easy-to-install

Test Procedure

And this is how it starts...

Test Objective

Quantify the torsional and chamber stiffness of the original wheel centre using the maximum tensile stress and part deformation data found through ANSYS simulations for the following load cases:

Braking + Cornering

Pure Braking

Pure Cornering

Torsional Stiffness

The wheel centre's tendency to resist torsion

Camber Stiffness

The wheel centre's tendency to resist camber bending.

.png)

Iterations

Cut back that mass.

Prototypes

I needed to start somewhere and iterated on the original design of our old wheel centres.

Original Design

Heavy

Clunky

Difficult to install

Mass = 0.78 pounds

Final Design

Mass = 0.54 pounds

Highlights

It works!

Designed 10+ iterations of the new wheel centre to reduce the overall mass by 31% (0.78 pounds to 0.54 pounds)

Failure criteria for all realistic loading cases fulfill the design requirement for a factor of safety of 1.75

Torsional stiffness increased by 27% in comparison to previous iterations

Created professional engineering drawings to receive manufacturing quotes