PRESSURIZED BEND TEST

Air reservoir structural endurance

.png)

Collaborative Project - Sep 2021 to Dec 2021 | Modal Analysis | CAD | Vibration Testing

Summary

Bend it until it breaks.

My first task at Tesla was to design an air reservoir bend test for one of their vehicles. This particular air reservoir needed to support very high bending loads and our current finite element analysis (FEA) models were unable to predict the load at which the reservoir would burst. Therefore, I needed to find the reservoir's ultimate failure load in which the reservoir bursts. To do this, I developed a bending test fixture and procedure to push the reservoir to its breaking point. With the data from this test, we could validate our current FEA models of the reservoir.

Design Objectives

Robust

Easy-to-install

Adaptable

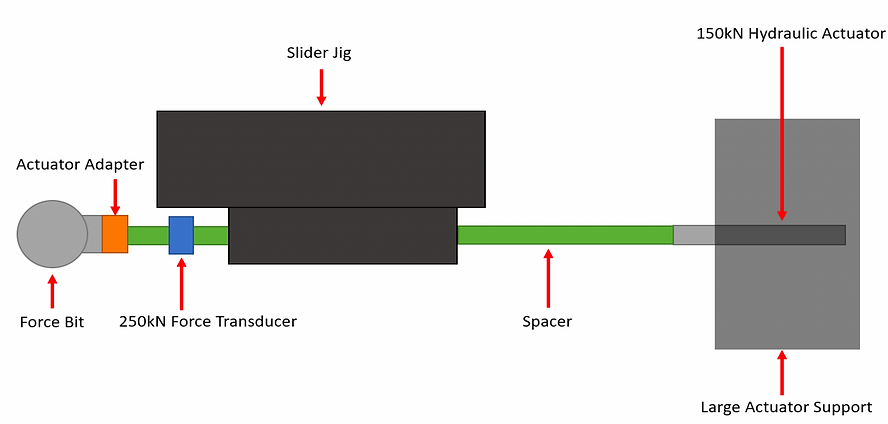

Test Layout

Plan it out.

Working closely with the vehicle testing team, I developed a test layout that worked for them and their means of installation. We wanted this test done well and for it to be set up efficiently. I also implemented their slider jig as a safety measure in case the fixture failed before the reservoir.

Prototypes

Its gotta be strong...

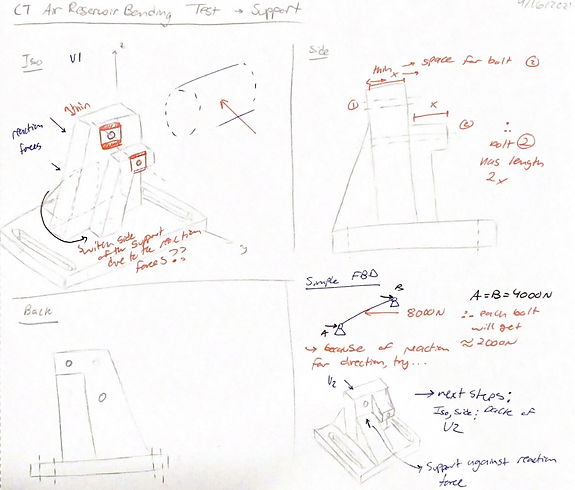

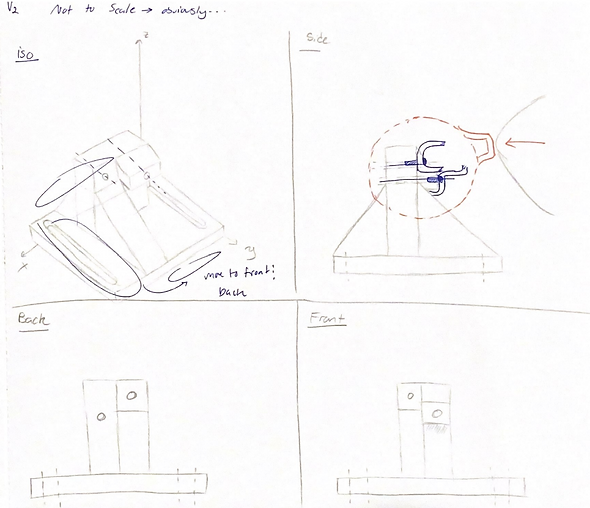

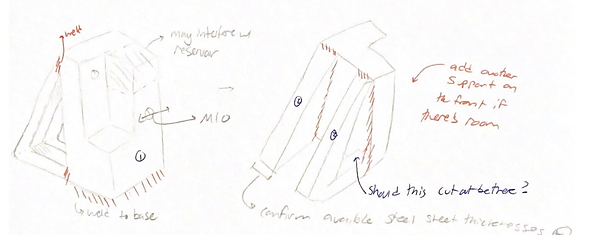

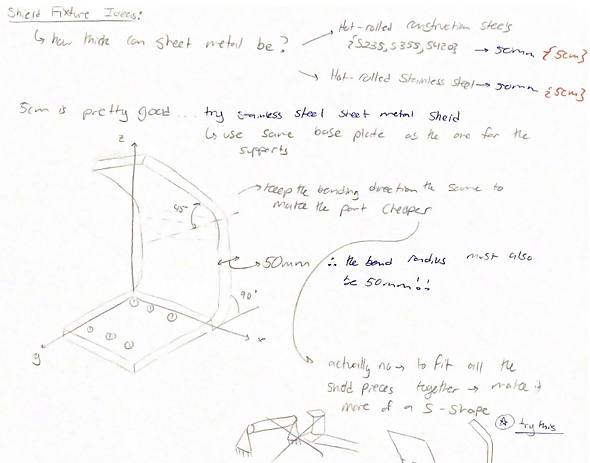

Sketches

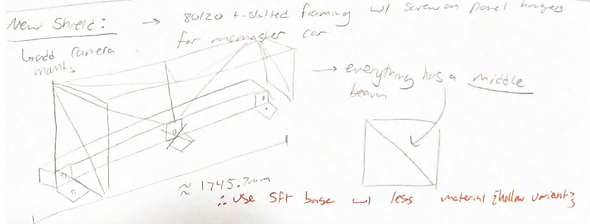

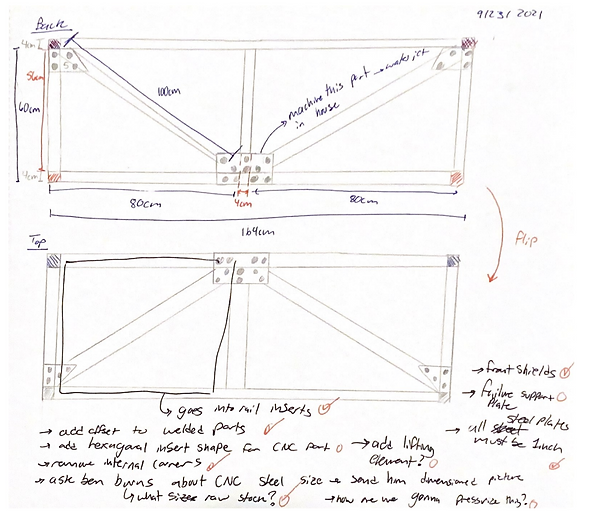

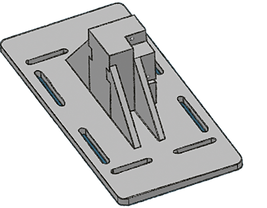

This fixture had two main parts - supports to mount the reservoir and a high-velocity projectile shield to protect the technician when the reservoir bursts

-

Reservoir Supports

-

High-velocity Projectile Shield

CAD Models

Easy-to-fabricate

Version 1

Stiff

Cheap

.png)

Version 2

Version 3

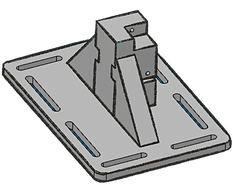

Final Design

Make it robust.

High-velocity Projectile Shield

Assembled by hand...

.png)

Highlights

Let's get testing!

Designed versatile and robust universal bending test supports which can be adapted to test future iterations of the reservoir

Fabricated and assembled an 80/20 aluminum x polycarbonate shield to protect the technicians while the test was running

Worked with reliability and test team to create a bend test layout which utilized high-force hydraulic actuators to apply the load

Reservoir endured up to 425% of the predicted ultimate force (Much higher than we though!)